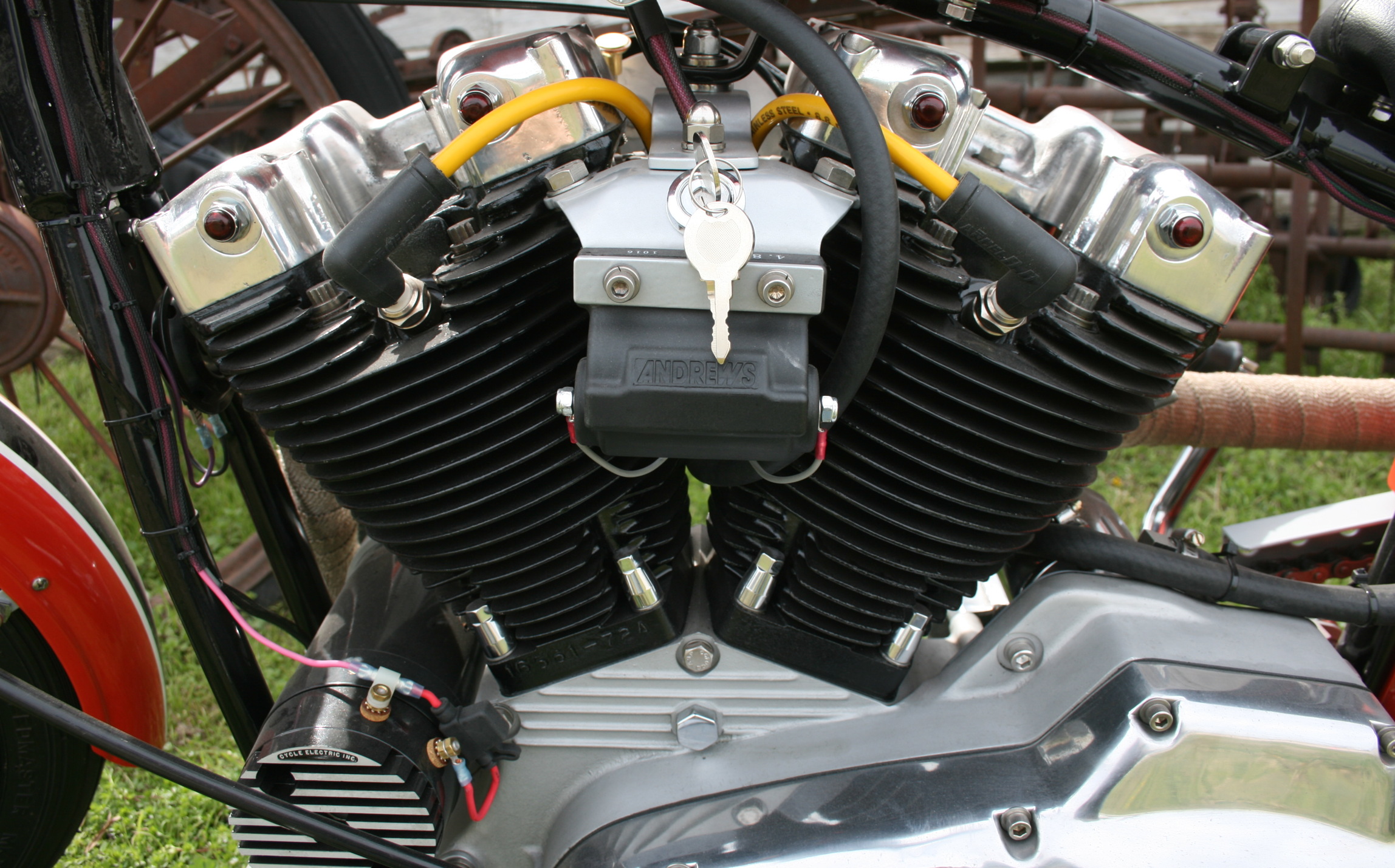

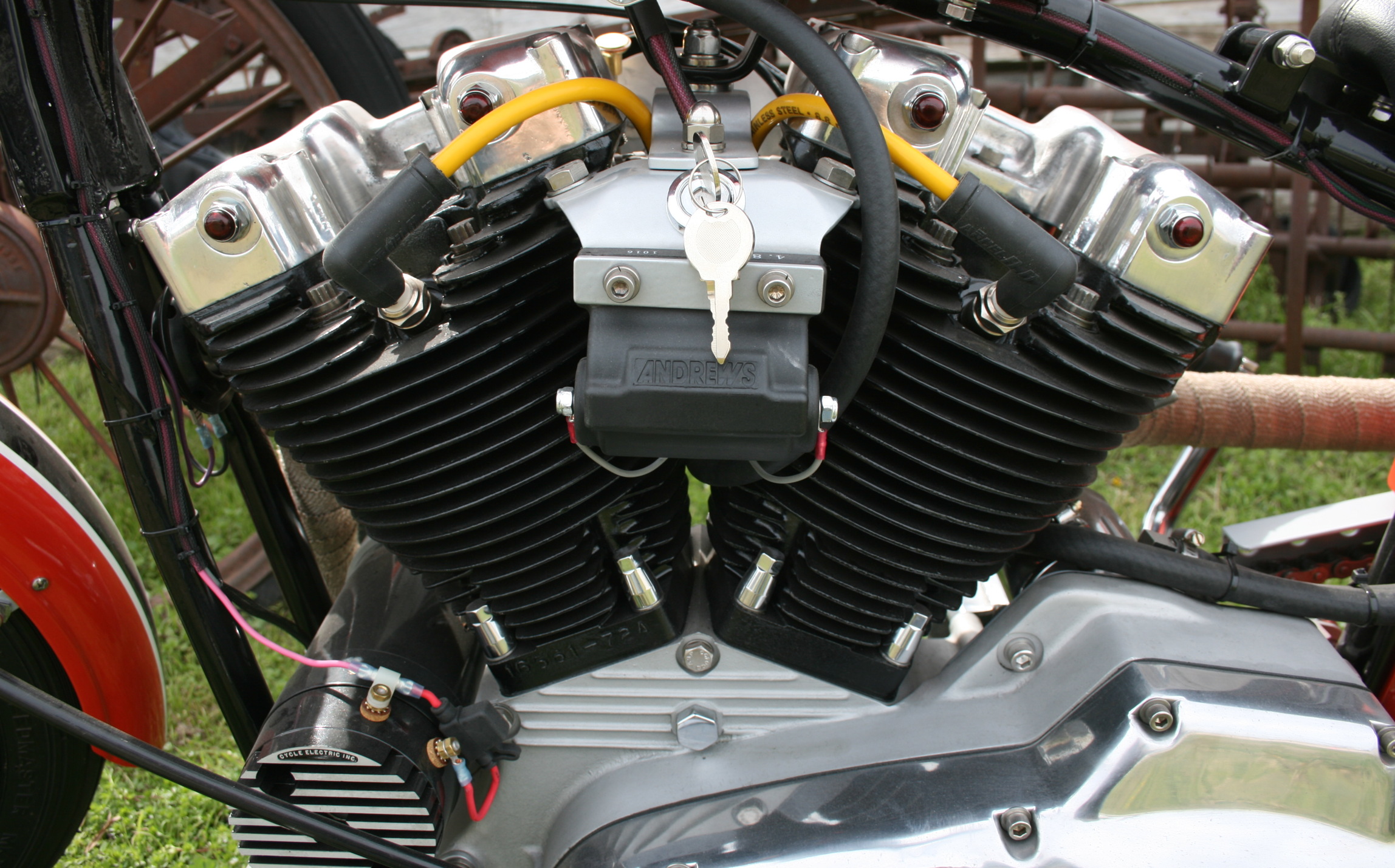

I had completed Project "X", a while ago and really wasn't looking to do another bike, but, when a guy made me an offer on a pile of junk I just couldn't resist. "Y" comes after "X" so this became Project "Y", otherwise know as The Orange Machine, yet another IronHeadCycle total build. I wanted to build a full on custom rigid frame chopper. The idea was to have just an engine in a frame with wheels with as few extra parts as possible. When you looked at the bike I wanted you to think it couldn't possible run and drive because it was missing pieces. To open up the area behind the rear cylinder, the oil tank was hand fabricated to look like part of the fender and the battery is hidden in the oil tank. Electric start and the associated starter, big battery, wiring etc. was totally out of the question, so this bike was converted to kicker only.

If you've ever built a custom bike, you usually discover that it looks better if the rear fender fits closely to and follows the arc of the wheel. This is especially hard to do on a swingarm frame because you have to allow for the swing arm travel and you have to allow for the fore and aft wheel adjustment to tension the chain. This is why most swingarm bikes have large heavily valanced fenders. I wanted to keep the fender small and tight to the wheel, hence the decision to go with a rigid frame. I could have used an aftermarket frame, but to avoid title issues I wanted to keep the original VIN. Hence the decision to use a weld on hard-tail. There are many styles to choose from. I opted for a VoDoo Vintage single down-tube version, I think it has the cleanest look. In order to keep the fender as close to the wheel as possible, I also decided to eliminate the slotted holes for adjusting the chain tension. I filled in the adjuster slots and drilled a simple hole for the rear wheel axle. Chain adjustment is done with an external adjuster and master half links.

I want to digress here for a moment and offer up some advice to those of you who are planning a do-it-yourself hard-tail conversion. First of all you need to plan carefully, dropping the rear and raking the front end may sound really cool. But, I've been asked to work on bikes that are so low that the kick starter arm hits the ground before it makes a full stroke. I've been asked to work on bikes that are so low that they have virtually no lean when the kickstand is down and are in constant peril of falling over. These are not issues you want to find out about after you roll your freshly painted/powder coated/chromed dream machine onto its wheels the first time. I say "asked to work on" for a reason, these machines are dangerous and I do not put myself in a position to be hurt by a customers bike. I do not take them into my shop. These machines have no cornering ground clearance and they will drag and throw you off just by getting snagged on an expansion joint.

Secondly, measure everything. You will be cutting up a highly engineered component and welding a big new section on it. Level the frame, find fixed reference points that you will not be cutting off, drop a plumb bob from those points to the floor, mark the locations, take notes, make a drawing, whatever you have to do to ensure everything is straight, square and true when you weld it back together. I've been asked to work on bikes that have had the hard-tail welded on so crooked, that the rear axle is out of level by ¾" from one side to another. Thirdly, plan your welding. Do not weld all the way around one frame tube and then just move on to the next. Tack weld one tube in place. Measure and adjust, then tack the opposite tube in place. Measure and adjust some more, then tack the opposite side lower tube, etc., etc. You get the idea.

Thirdly, after you have solid tack welds in place, put your front end and wheels on. Then put the bike on the ground, make sure you've got the look you want, make sure the kick start clears the ground, make sure the kickstand works. Now is the time to make corrections. I do this with every custom build I do, it takes more time, but it is the only way you'll know you are producing a working product.

Finally, after you are satisfied all is good, you may finish your welding. Once again, do not plan on welding all the way around a tube all at once. Weld 1/4" of the way around then weld the opposite side. Hot steel expands and you will create and lock in a twist or a warp if you do not weld evenly around the frame. Enough digression, back to the Orange Machine.

I also wanted to clean-up the left side of the rear wheel. I did this by using a sprocket/rotor brake set up. This particular set up is a V-Twin kit. IT IS NOT BOLT ON. There was quite a bit of hand fitting and modification to get it to work. The caliper had to be milled to clear the hub and spokes, the brake disk bolt holes had to be countersunk, spacers had to be made and modified, the brake anchor that came with it was discarded and a new one was machined. The sprocket/rotor package is not a beginner bolt on. You have to work for it.

LePera shipped me a seat pan, it was modified, shipped back to LePera and then they covered it. Hand made oil tank, hand made chain adjuster, hand made forward controls, hand made pedals and linkages, hand made chain guard, hand made oil filter mount, hand made timing cover, hand made sissy bar/fender brace, hand made top engine mount/coil bracket/ignition switch mount. Right side brake and sprocket. Stainless steel spokes. Weld in single down tube hard tail. Rubber mount, bottom mount gas tank. Completely rebuilt engine and trans. The list goes on and on.

This bike is for sale: $25,000.00

Buy and Sell Ironheads - Buy and Sell Ironhead Parts - Rebuild Ironheads - Specialty Work - Wheel Building and Lacing - Wiring - Engine Rebuilding - Transmission Rebuilding - Flywheel Trueing - Line Lap Case Bearing Races - Lap Rod Races - Valve Jobs - Install Hardened Seats - Cylinder Boring - Heliarc Welding - Lathe and Mill Work - Powder Coating

All work is performed in house in a fully equipped shop.

IronHeadCycle LLC

North Texas

United States of America

Phone: 940-297-5009

Send a Message to IronHeadCycle