The full sized version of pictures on this website can be viewed by right clicking on the picture and selecting "VIEW IMAGE", then use your browser back button to return to the web page...

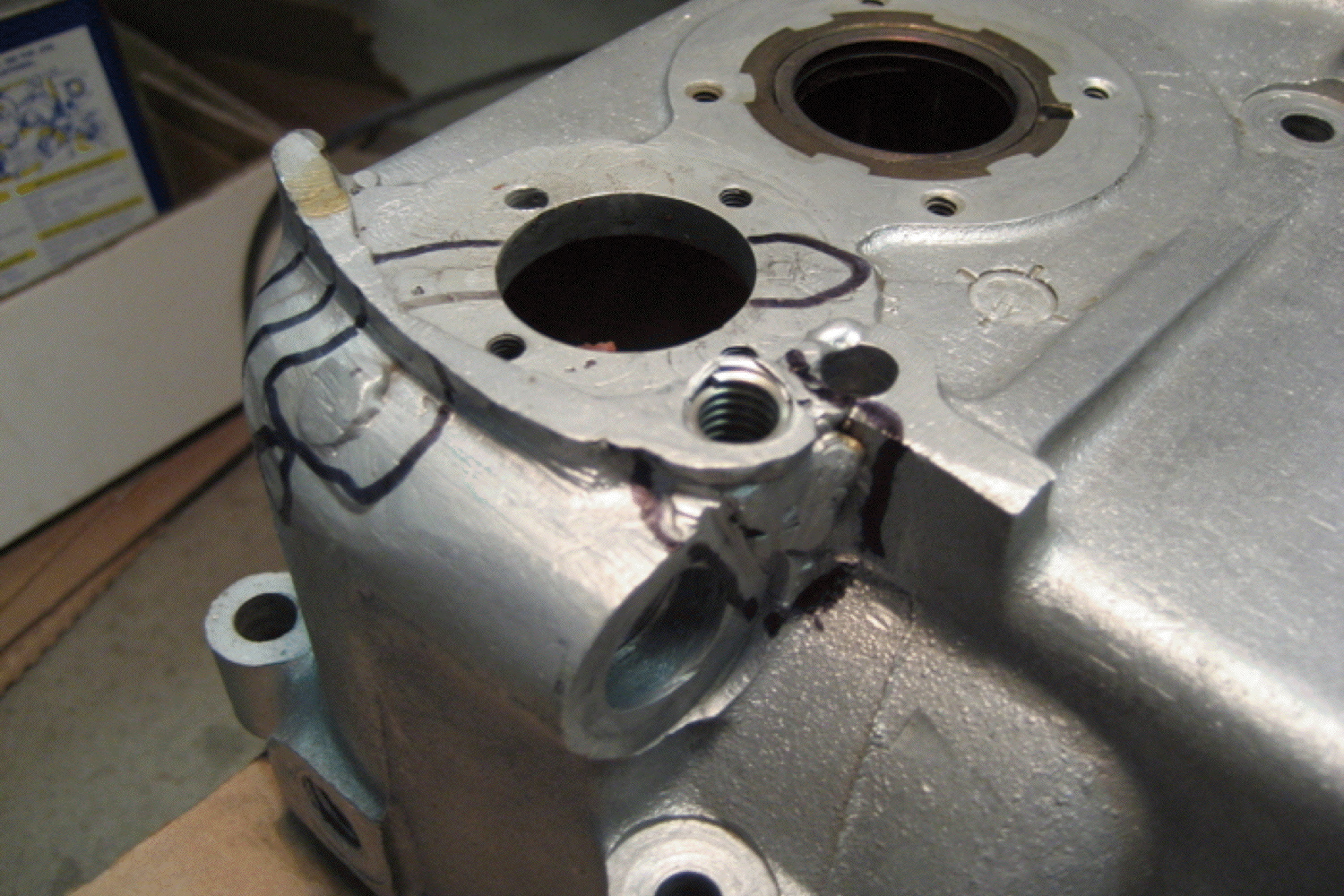

Before Repair

At some point in the past the counter shaft bearing blew out and took the case boss with it. A previous owner attempted a somewhat ingenious, if not ill-advised, repair. He milled out the damaged case, machined a new bearing support boss and bolted it to the case with four 10-32 screws. The four 10-32 screws were not capable of carrying the load and the repair failed.

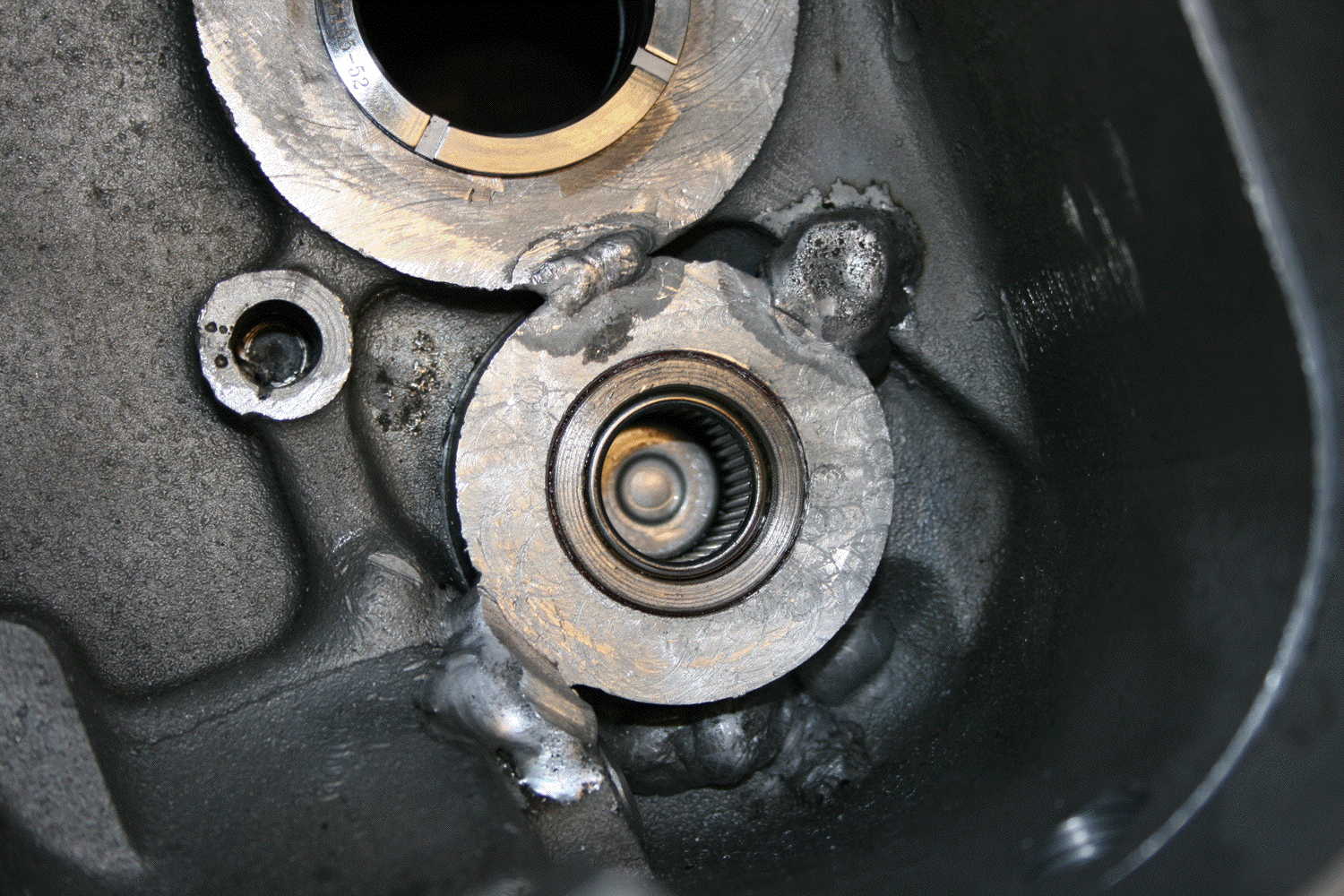

After Repair

I milled out all the damage to just past the four drilled holes, machined a new boss for the counter shaft bearing, aligned it with the trap door using a fixture I made. The case and the boss were deeply chamfered all the way around to allow for deep weld penetration. The boss was welded internally to the case.

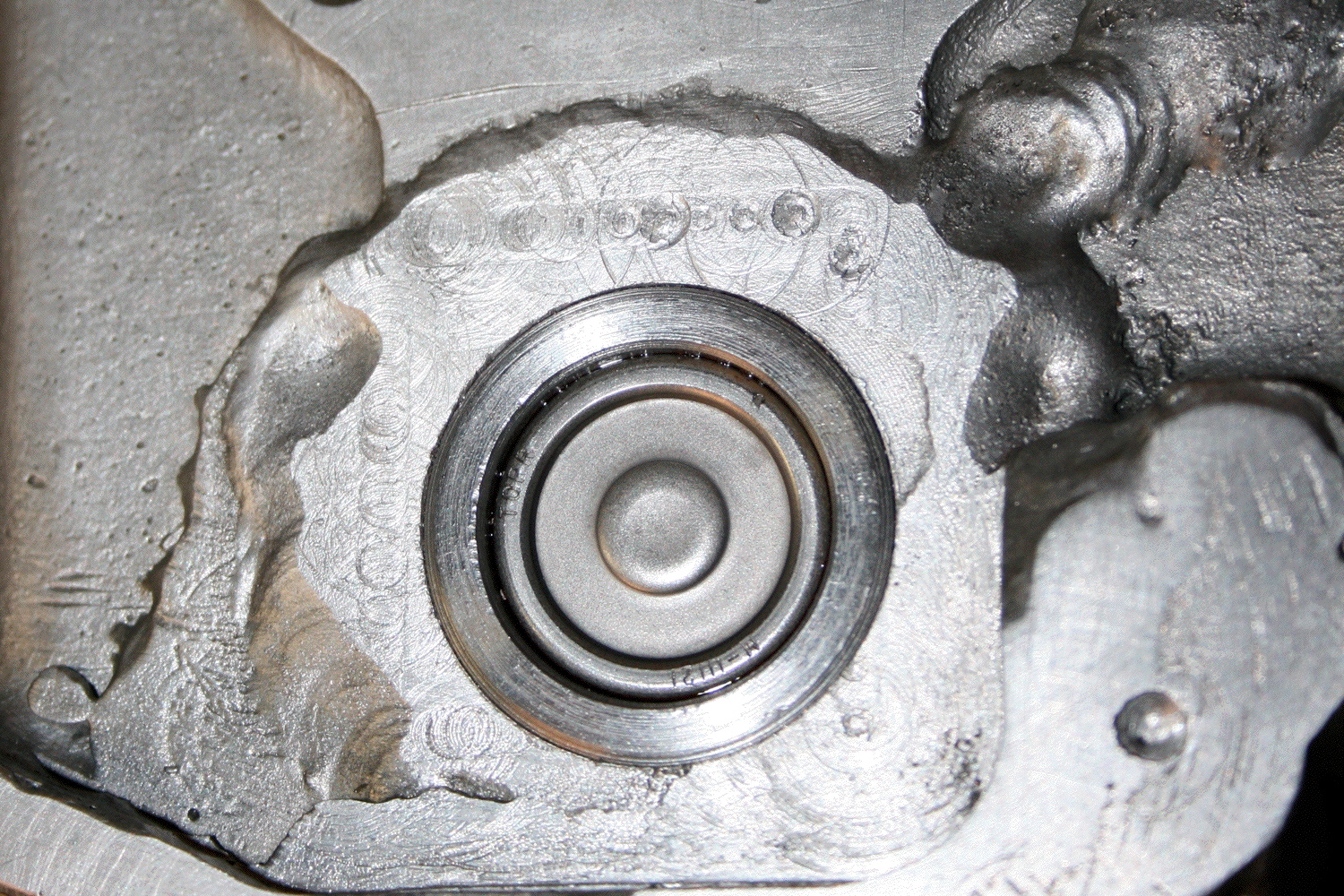

After Repair

I also machined a steel reinforcement for the bearing that was pressed into the case. The external weld was milled flat to make sure it cleared the chain and sprocket.

After Repair

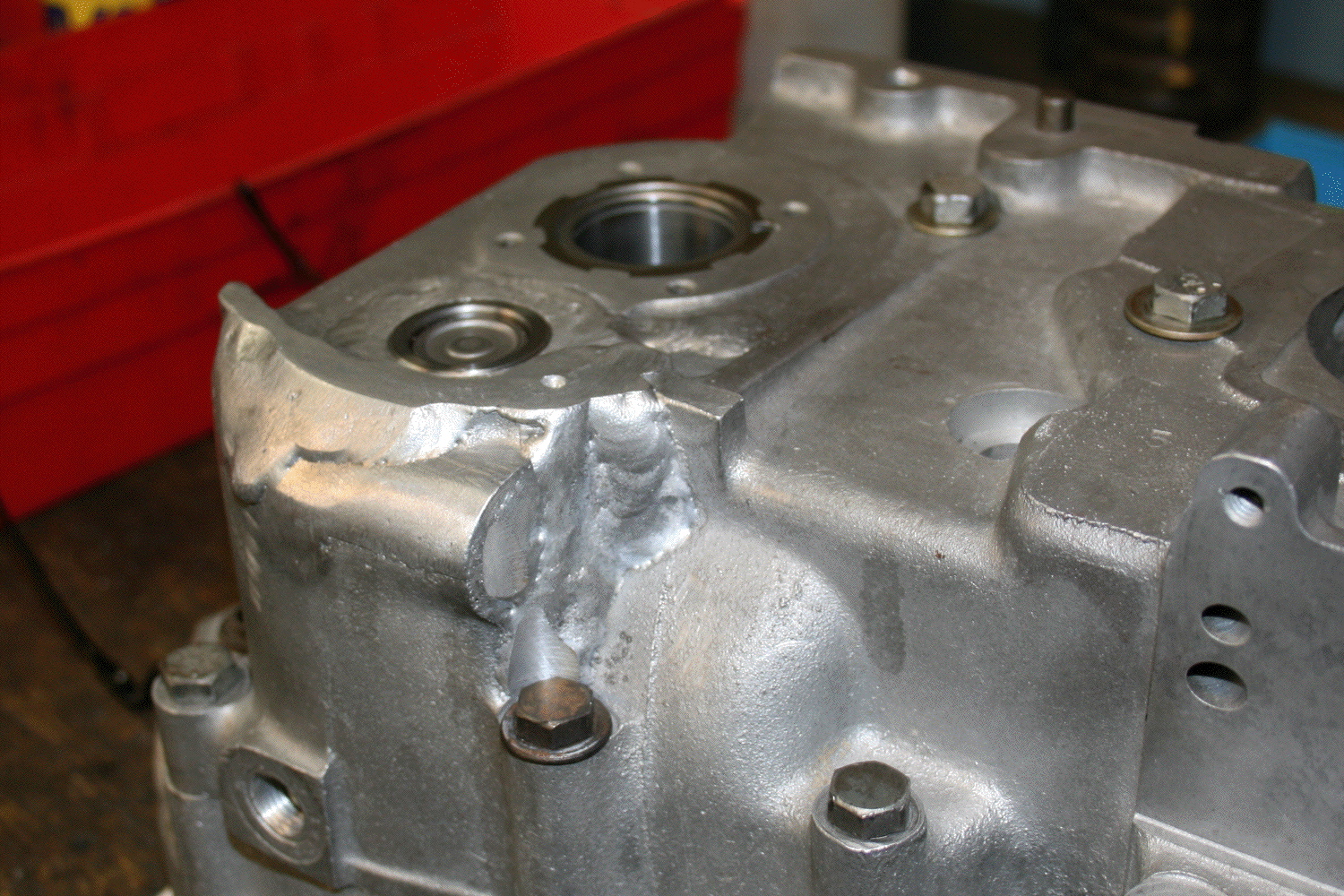

There was a spiderweb of cracks emanating from the broken out counter shaft boss, all those cracks were welded. The shifter fork shaft which is usually plugged with a welch plug was also welded shut. The cracked out sprocket cover bolt hole and alignment dowel hole were also welded shut. A filler plug for the speedo drive was also fabricated and the speedo drive welded shut. This whole area is greatly reinforced over the original.

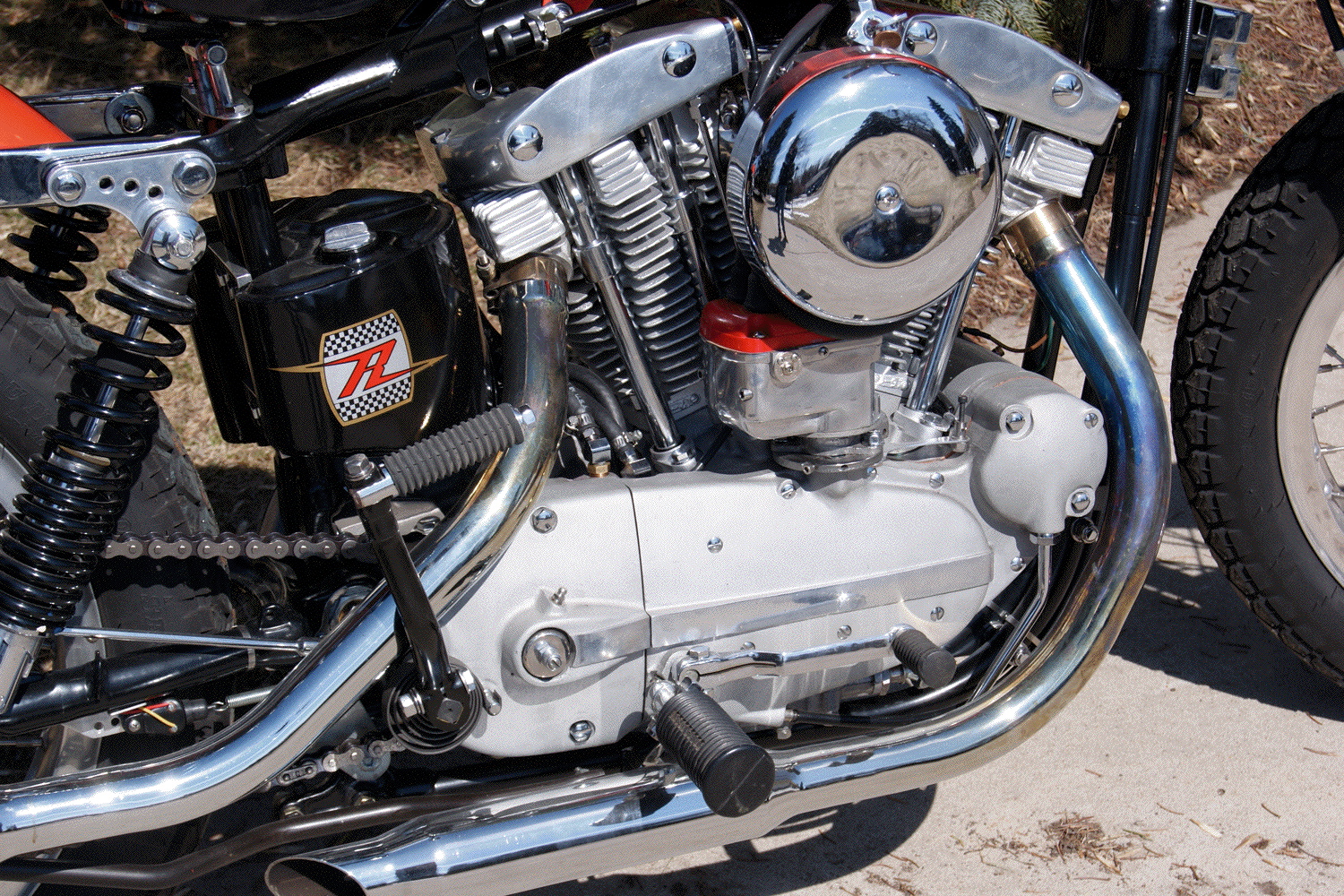

Finished!!!

After IronHeadCycle Crankcase Repair