oil

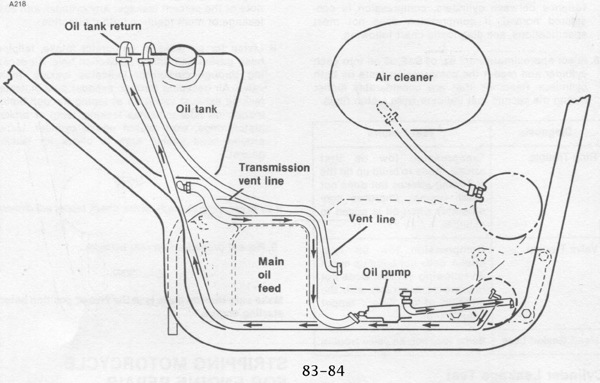

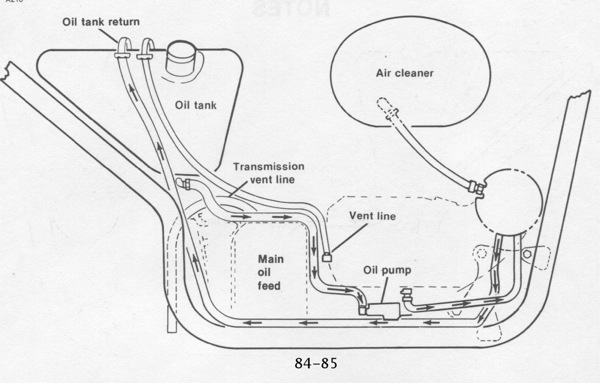

Question: Hey there! I have recently stumbled upon your site just google-ing Sportster clutches. And I must say that your site is awesome. I read the whole story/instructional on building the Sportsters... awesome looking bike. It seems that you know what the hell you are doing with Sportster so I thought I might ask you a question about my late 84 XLX1000. I'm kinda paranoid about the oil flow. Is there a trick that you might know about testing your oil pump and the flow. I know if it ain't broke don't fix it, but I'm trying to learn a little here. Not used to Harleys.

Answer: (These are the questions I love to answer, a little sucking up goes a long way.) To check whether oil is reaching the farthest parts of the engine, the rocker boxes, take the socket cap plugs out of the rocker-boxes and see if oil dribbles out while the engine is running. Also take the cap off the oil tank and look for return flow, In both cases oil flow will be sporadic at idle and increase as the engine is revved.

Question: I have a 74 that ran up until last weekend. Now when I turn over the starter, oil comes gushing out the breather. Big problem or little problem?

Answer: Actually, oil coming out the breather may not be a problem at all. The check ball on the oil pump may stick or leak allowing oil from the tank to fill the crankcase. When you crank or start the engine oil is then forced out the breather. As long as it stops after a minute or two you are probably OK. The longer the bike sits between starts the more oil there will be. Put a clean container under the breather and just pour the oil back into the tank.

Question: I have a 74 Ironhead, I changed out the head gaskets, the lower engine ones and decided to put new rings in. Now after about 15 minutes of running oil wells up over the push rod covers. Any ideas?

Answer: Too much oil or too much pressure in the crankcase. Were the holes in the head gaskets for the oil drain backs correctly aligned with the holes in the barrels and heads? If they weren't the blockage would fill the rocker boxes with oil that would eventually have to drain back down through the push rod tube covers. You could have very poorly fitted rings that are allowing a lot of blowby into the crankcase thus over pressurizing it; oil will eventually leak from everywhere.

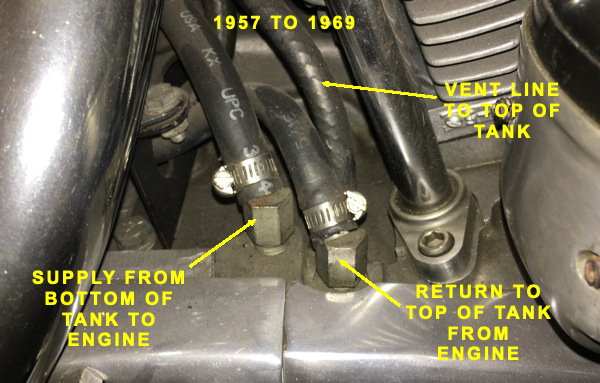

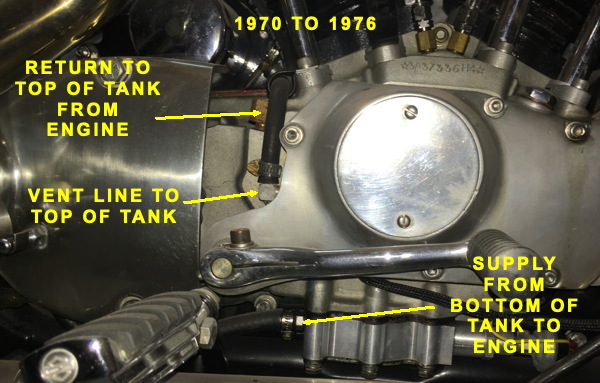

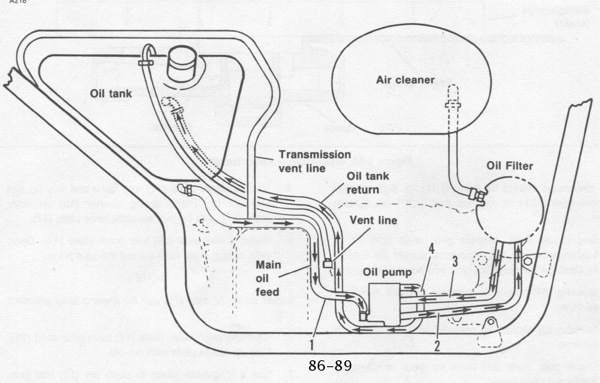

Question: How do I hook up my oil lines? (By far the most commonly asked question.)

Answer: See the pictures below:

It Runs Crappy

Question: Can you give me some reasons why my 68 XLCH backfires consistently?

Answer: Manual or automatic advance? Compression? Are the valves adjusted correctly? Are the points set right? Is the timing set right? Are you absolutely sure it is set right? Old gas? What kind of carb? Does the intake leak? Cracked coil? Clogged low speed jet? Clogged fuel filter? Dirty plugs? Bad plugs? Check all that shit out, let me know what you find and then get back to me. Or else just wave a magic wand over it while sprinkling fairy dust... If you want a better answer you need to be more specific about what the problem is and what you've done so far to correct it and what kind of shape the bike is in. Vague questions get vague answers...

Question: I have a 69 Ironhead electric and kick start. my dad and I just got it to turn on which is great but now she backfires. Do you have any suggestions ? We put new points condenser and spark plugs.

Answer: When is the last time it ran? Did you ever have it running? Manual or automatic advance? Compression? Are the valves adjusted correctly? Is the timing set right? Are you absolutely sure it is set right? Old gas? What kind of carb? Does the intake leak? Check all that shit out, let me know what you find and then get back to me. Or else just wave a magic wand over it while sprinkling fairy dust...

Question: I recently bought a 1972 Ironhead sporty with a 1000cc. Its kick only and hasn't been tinkered with too much. I tried to kick it over but with no success. Any tips on what might be going on?

Answer: When asking for technical help you must always be very specific. What do you mean "I tried to kick it over but with no success." The kick lever won't go down? The kick lever goes down and it doesn't engage the engine? The kick lever goes down, engages the engine, the engine rotates normally and it just won't start? Or my leg is broken and I've had no success trying to kick it? I'm not trying to be a smart ass, but any of the above are possible and they all have many different causes and solutions.

Reply: No sweat man, I know you have to get a lot of stupid as fuck questions all the time. The kick lever goes down all the way and engages the engine the engine rotates normally it just wont start.

Answer: Always go back to the basics, fuel, spark, compression and timing. First of all take off the air cleaner and make sure the accelerator pump squirts gas; if it doesn't suspect a fuel supply problem. Even if it does, the jets in the carb can be plugged with crud. Take the plugs out and stick your thumb over the spark plug hole while you're kicking it, the compression should blow your thumb off. If it doesn't the valves may be adjusted too tight or you've got serious internal damage, bent valve, hole in a piston etc. While the plugs are out, plug them back into the lead, lay them on top of the engine and kick, you should see a spark (do this in a garage; a bright sunny day will make the spark hard to see), if you don't you've got bad plugs, bad coil, bad leads, bad points or condenser or some kind of wiring problem. Get yourself a manual, and learn how to do a down and dirty check on the timing, make sure the points are adjusted correctly. Its been my experience the timing can be off a tad and the bike will still run basically fine.

Swingarm

Question: I'm starting with my own 74 project so far so good until I got to the swingarm. The threads are screwed up from the person before me. I'm not sure how the bike was ridden as the swingarm bolt was missing!! I'm a bit on the cheap side and really do not with to but a new one, any taps this size are around 200 bucks might as well buy a swingarm. Any suggestions????

Answer: As a matter of fact I do have some suggestions. Get a couple of the big swingarm bearing retainer jamb nuts, make sure the threads are good, clean them up with a thread file if need be. Get something sharp and pointy and drag it through the thread valleys on the swing arm, you'll be sort of re-cutting the threads by hand. Hopefully at least the last thread or two on the swing arm is good so you can at least start the big nuts. Then, assuming you can at least start one of the big nuts, get some fine valve grinding compound and lather up the threads on the nut and swing arm, then start working the nut in, back and forth, back and forth, and you just might get the threads cleaned up. It takes a while so be patient, I've saved a few swingarms that way.

Question: I rebuilt the swing arm bearings and installed them with the races to the inside, wide open end facing outward, then the bearings with narrow end inward to the races just like in a wheel, right?

Answer: This is how the swingarm bearings are supposed to be set up... Your description sound like yours are in backwards...

Question: I am wanting to swap the rear over to disc and just need to find a decent priced floating rear caliper. I haven't been able to find a 79 swing arm and don't want to rigid it. I have a 78 Ironhead XLCH. Any suggestions would be awesome thanks man.

Answer: Although the 79 swingarm makes a better installation, it is not absolutely necessary. Most disk brake calipers can be modified to bolt to a bracket that will fit over the axle and can be anchored with a torque rod bolted to the side opposite the caliper and the other end of the torque rod bolted to boss welded to the stock swingarm, you'll have to fabricate something.

Question: My son got a 72 Ironhead for his 18th birthday and has rebuilt it and been riding for this past year, we got all the bugs worked out and now we would like to go with disc brakes on the rear, he is in need of a new wheel and we figured we should get the brake setup and wheel all together. If you know the combination needed to do this conversion and possibly have all the necessary components.

Answer: There is no kit available for such a conversion, the rear wheel and brake off of a 79 and later would be a good starting point. The biggest part of the problem is that your bike is a right side shift and the disc brake set ups are all for right side brakes. So you'd have to figure out how to mount the master cylinder and pedal on the left side of the engine.

crankcases, connecting rods and bearings

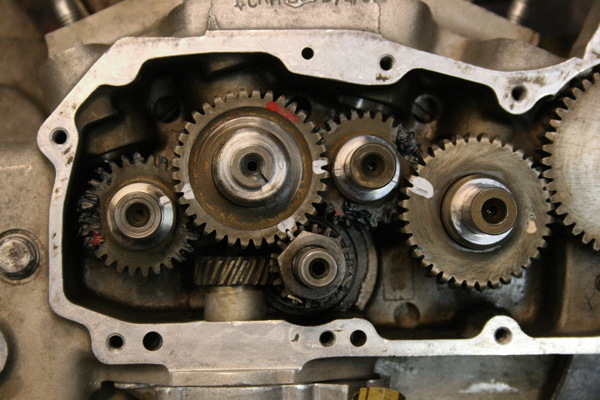

Question: I need help trying to figure out how to align the gears for the cam rollers on 77 XLCH?

Answer: This should help:

Question: I have a 1975 Sportster electric start, can you install a kicker also?

Answer: Yep, that bike can be kick and electric...

Question: This may be a stupid question but I will ask it anyway. I have a 1980 XLH1000 that needs to be rebuilt. I am tearing the engine down and am at the point of removing the engine sprocket nut and the clutch hub nut. Do those two nuts have traditional threads or are they reverse threaded?

Answer: Conventional threads, NOT left handed.

Question: Do know what size rod bearing, race, and crankpin that will work together.

Answer: The pin and the bearing races do not come in different sizes. The bearings do come in different sizes. The races are hand lapped to get the best fit using the lapping tool. Fitting rod bearings is on the advanced list of Harley mechanicing. No offense intended, but if you are having to ask questions like this you probably are in a bit over your head.

Question: Which way do the connecting rods go in ?

Answer: The forked rod is for the rear cylinder. No offense intended, but if you are having to ask questions like this you probably are in a bit over your head.

Question: I'm looking for a location/fitment chart that shows where each length of the primary cover bolts go, and a simple chart of how to put the clutch cable back into the ramp, do you happen to have this available?

Answer: Of course the smart ass answer is the parts book. Anyway the screws are ¼" x 20 x 1½" qty 2 and ¼" x 20 x 2¼" qty 8. You'd best buy a manual to figure out how to install the clutch cable...

Question: Do you have any tips for fixing a stripped out sight hole for the timing marks on the flywheel?

Answer: Those are a bitch to fix without taking the engine apart. That thread size is ⅝"-18. The stock plug for that hole is not as long as the hole is deep a lot of the time there might be 5 or 6 good threads at the bottom of the hole. If you can find a plug ¼" longer than the stock HD plug you might be able to catch the good threads at the bottom of the hole. Make sure the plug is not too long or it will hit the flywheel. Unfortunately a ⅝"-18 bolt has a head on it that will hit the primary part of the case so you can't just cut off a bolt to make a longer plug. A ⅝"-18 socket cap will work. Be aware that most standard bolts are not threaded all the way to the head, a standard bolt will need to have the top of the threaded part relieved on a lathe so that it will bottom out on the case. Some auto parts stores sell a self tapping oil drain plug used for fixing stripped threads in oil pans, that might be your best option until you have to split the case for some reason...

Speedo Drive

Question: I have a custom 1981 Ironhead, and I am trying to figure out how to hook up a speedo. Does it hook in to the trans or do I just have to go with one that goes on to the axle that acts as a spacer.

Answer: There is no drive gear on an 81 trans, you'll have to hook it up to the front wheel...

Question: I have a 1972 Ironhead and the previous owner welded shut the speedo sending unit hole. I want a speedo on my ride. Any idea what I can do?

Answer: You are better off with that hole welded shut, that is a very weak area of the case and the hole makes it even weaker. Get yourself a speedo drive that works off the front wheel, they are commonly available and will work fine.

Other Stuff

Question: I am turning a 74 Sportster into a old skool bobber. The front is too tall with the stock narrow front end with the stock 19" wheel with stock tire. Could you give me a couple of ideas how to lower the front. We thought about cutting the fork springs but don't know what that will do to the ride.

Answer: Cutting the fork springs will make the fork bottom out and the ride will suck. Send the tubes to an outfit named Forking by Frank http://www.frankmain.qpg.com/. They can shorten the tubes to whatever length you want, you can then cut the springs to match the tubes.

Question: Can you answer this question? Can an EVO Sportster fit into a 1966 Sportster frame?

Answer: Yes I can. Nope, an EVO engine is about 1.5 inches taller than an Ironhead; it won't fit in a 66 frame without a bunch of bending, cutting and welding.

Question: I just bought a 2000 Sportster Sport and the previous owner laid the bike down and scraped the left bottom shock absorber. Can you take the shocks apart to replace the scraped part?

Answer: Yes you can take them apart. I don't know for sure but I bet Harley won't sell the piece parts, they'll try to make you buy a whole shock...

Question: Do you have any idea what the field coil resistance is supposed to be for a XL 12VDC generator? I have one that I am working on for a friend and I think someone put 6VDC coils into the 12VDC housing.

Answer: This is what I come up with. There are two types of 12 volt coils, they can be either 12.6 ohms or 5.2 ohms. The 6 volt coils should be 3 ohms.

Question: I miss measures on the different tools, especially the tool used for locking the clutch basket and the engine sprocket (the 2 plates with bolts and pipe pieces through) I need the exact length and width of the plates. I have no tools that can measure that space...

Answer: The tool you need to measure the space between the sprockets is a fucking ruler. That's what I used. Any of the stuff on my website take a certain amount of mechanical aptitude. If you don't have enough mechanical aptitude to figure out how to lop off two chunks of flat stock, you probably don't have enough aptitude to be working on the bike. So get a ruler and figure it out...

Question: I'm 16. My parents bought me a 1982 25th anniversary Ironhead XLH Sportster and its bone stock. I've been getting used to it and now I think it's time to do some needed care and modifying. I've talked to many people who also had a Sporty as their first bike and, of course, did some things to get more power out if it. I'm on a really tight budget but would love to work with you (you have a good rep.) A guy who named his bike "Big Twin Killer" told he had his 1000cc Ironhead "same as mine" bored out .030 and had a really nice valve job done on it. If I bored my jugs .030 over what would the cc be in them? Can I get a few basic tips and advanced list of things on how to get some more horses out of my Sporty? My bottom line is, "what can I do?" I don't want a race bike (I don't even get close to the high rpm so a huge cam is pointless) but I want some more kick to an old motor! (To and from school, 65-70 on the highway.)

Answer: Grasshopper, one must learn to walk before one can run. I've been working on these things for 35 years and still don't know all there is to know about just keeping them running. So I know you have a lot to learn about the basics. You have a motorcycle that is 26 years old. Every movable part on the machine needs to be taken apart, cleaned, checked and re-greased. Wheel bearings, steering bearings, swingarm bearings etc. The oil tank needs to be cleaned out and 26 years worth of sludge needs to be scraped off the bottom of the tank. The front forks need to be cleaned out, the brake fluid needs to be flushed out, etc, etc. You should go over the wiring harness and look for chaffed areas and electrical tape covering up bad wire splices. You need to refine your technique for installing the intake manifold so that it doesn't leak. You need to refine your technique for adjusting push rods (trust me on this a little too loose is better than a little too tight). You must refine your technique for peering into the timing plug hole to check the timing. You must refine your technique for jetting and adjusting finicky old carburetors. Did I say "refine your technique" about four times. I'm sorry, you'll have to develop a technique first. For 100 years Harley owners have been bent over peering into the timing plug hole, getting sprayed with hot oil, while checking and adjusting the timing. Welcome to the club. Seriously, the first step to high performance is to make sure you are not giving away any HP because the basic machine needs attention somewhere. Once you know how and have done all the stuff I have talked about, then and only then will you need to look elsewhere for more power. Stock, that bike is probably good for 60 horse. Throw away a couple horse for timing that is off, a couple more for a little intake leak, another pony or two for a carb that needs some rejetting. Hopefully you get the idea. Now consider that old crud and pieces of metal floating up out of the sludge in the bottom of the oil tank and tearing up the engine a little at a time. Maybe your chain is too tight and every time the swingarm bounces up and down you tear up the trans main shaft bearing and race. Or maybe your swing arm doesn't bounce because the bearings are all rusted and pitted. Don't be too pissed off at me, I am serious about the advice I just gave you. You really do need to become one with the machine first... To answer your question, boring the jugs .030 will net you about another 2 ccs per jug, it is pointless from a performance standpoint. Unless of course the jug has damage, scoring etc. A good valve job is always nice and may actually get you a pony or two. Pretty much all Sportsters are Big Twin Killers. The BT guys won't admit it, but most of them will loose to a Sportster every time... The single easiest thing you can do to change the feel of the bike is to change the chain front sprocket, less teeth = you accelerate faster, more teeth = you lower cruise RPM. That sprocket is available with anywhere from 19 to 24 teeth. You'll have to grind some metal out of the sprocket cover to make the 24 tooth fit. Believe me 2 teeth makes a big difference. It doesn't change the HP any, but it makes a world of difference in the way the bike performs.