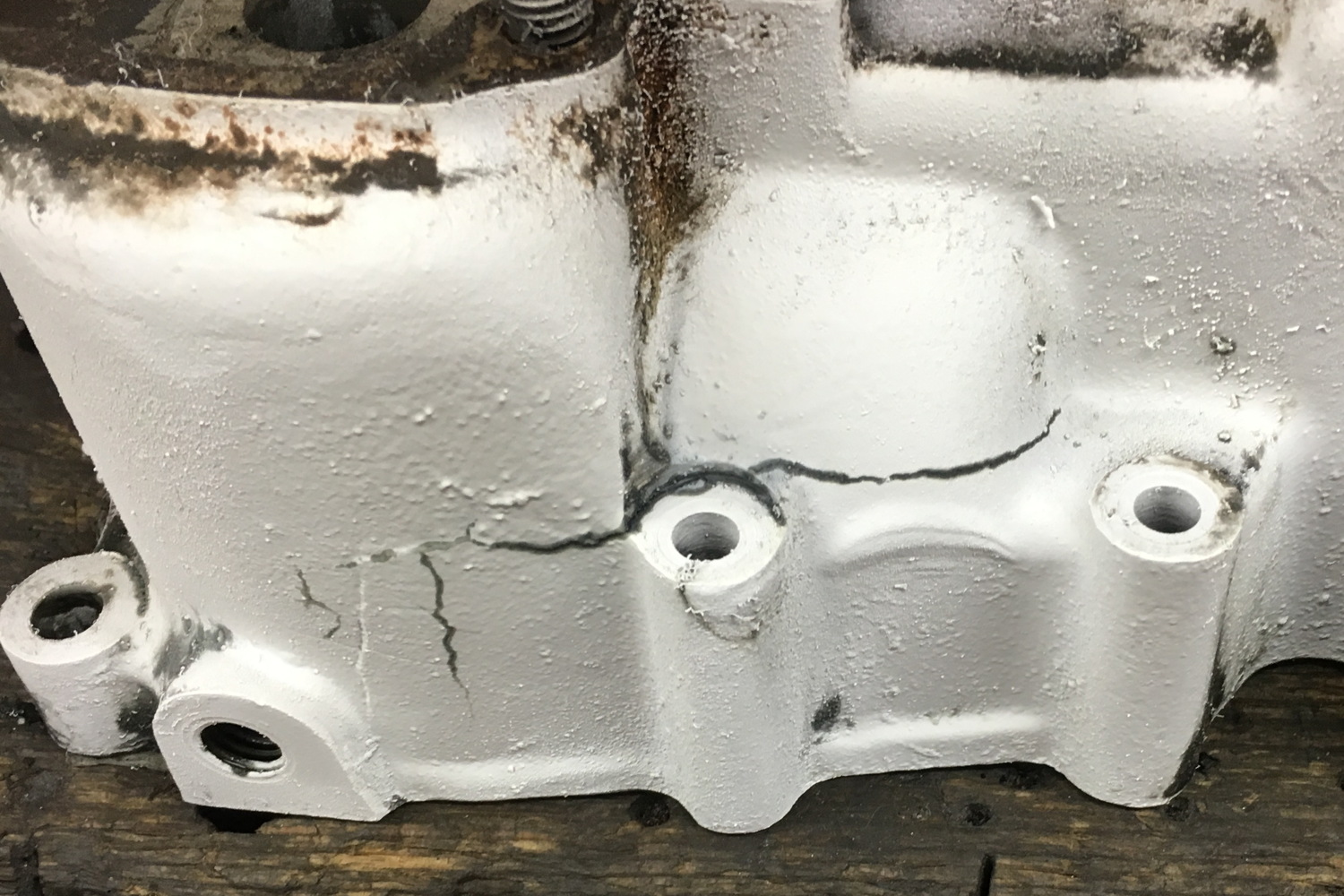

REPAIR EXAMPLE 1

On the left is a case that had some fine tight cracks propagating from a larger crack. In order to find the extent of the damage the case was sprayed with developer fluid which dries as a white powder and draws oil out of the crack and makes the crack show as a black line. On the right is the repaired case.

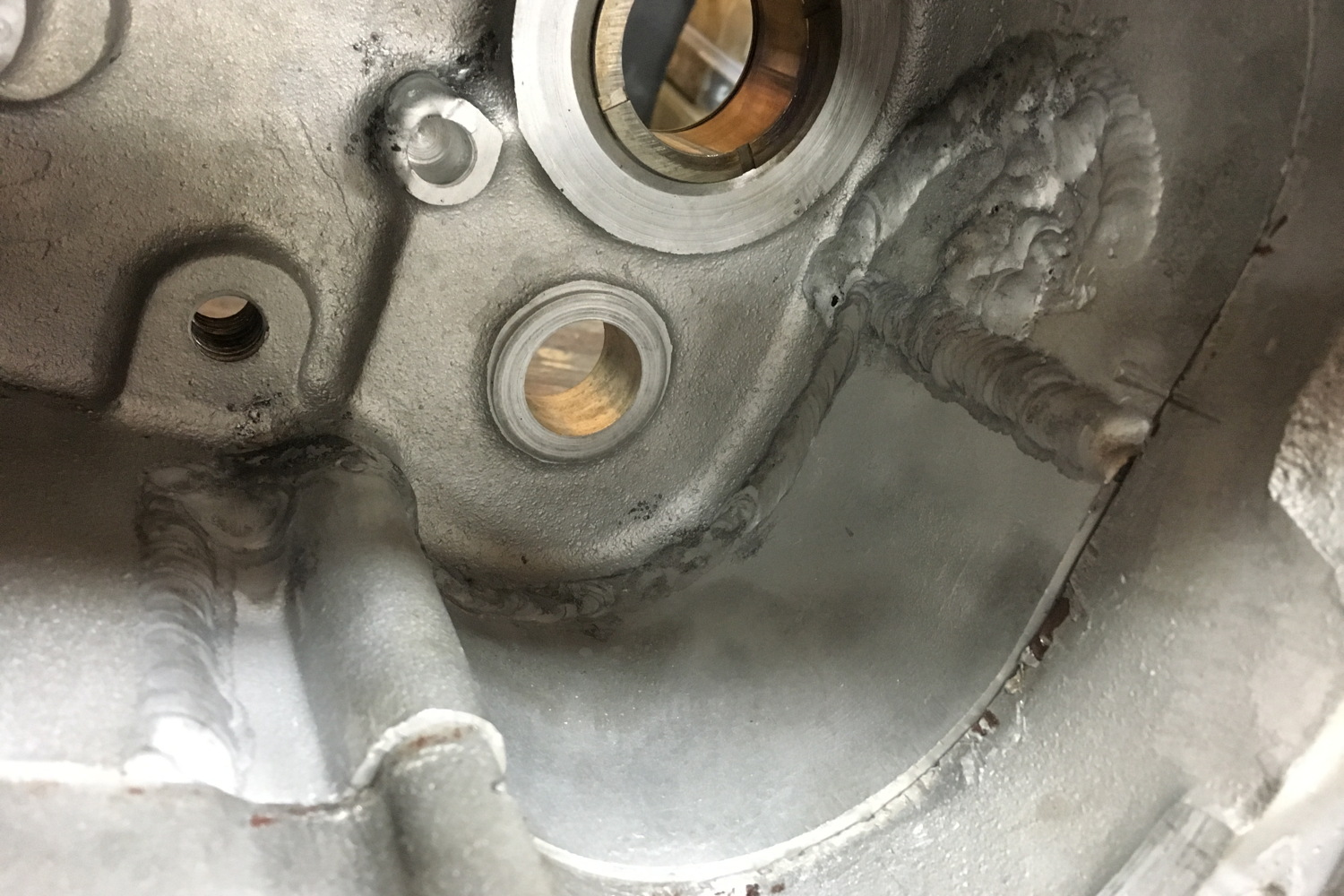

Repair Example 2

Not for the faint of heart. In a repair like this, the cases are bolted together and heated up in an oven to prevent warping. I think it is essential to weld the inside and outside. The wide gap between the repair piece and the case is a good thing, it allows for the deep weld penetration needed for a strong weld.

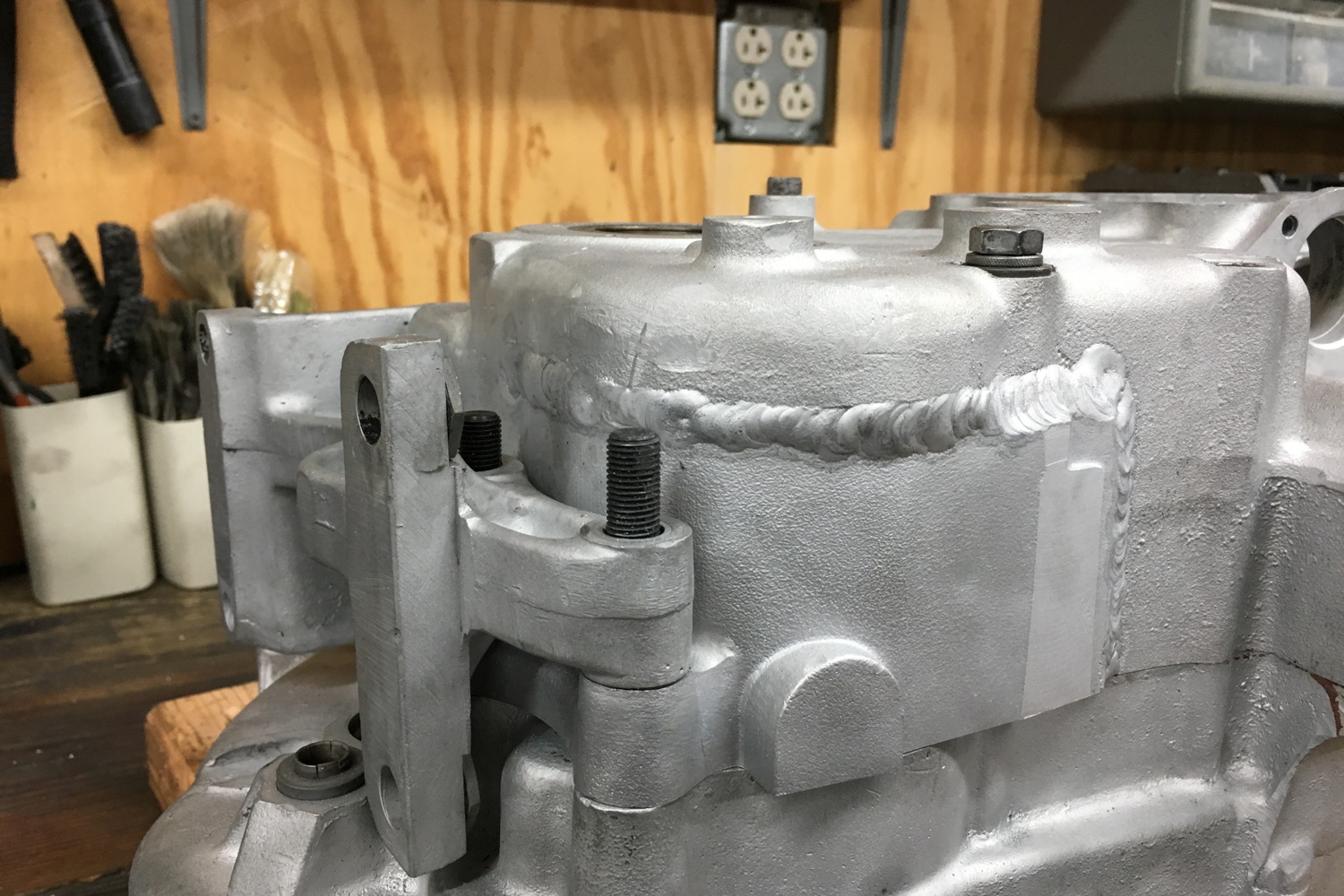

repair example 3

I've actually seen two engines with exactly this same damage. One was an engine that the owner just recently bought from a Harley dealer and the crack was filled with epoxy!!! The dealer failed to disclose the damage. Buyer beware... I believe this damage was caused by a collision rather than the gears trying to escape.